Parquet

An element7 Signature

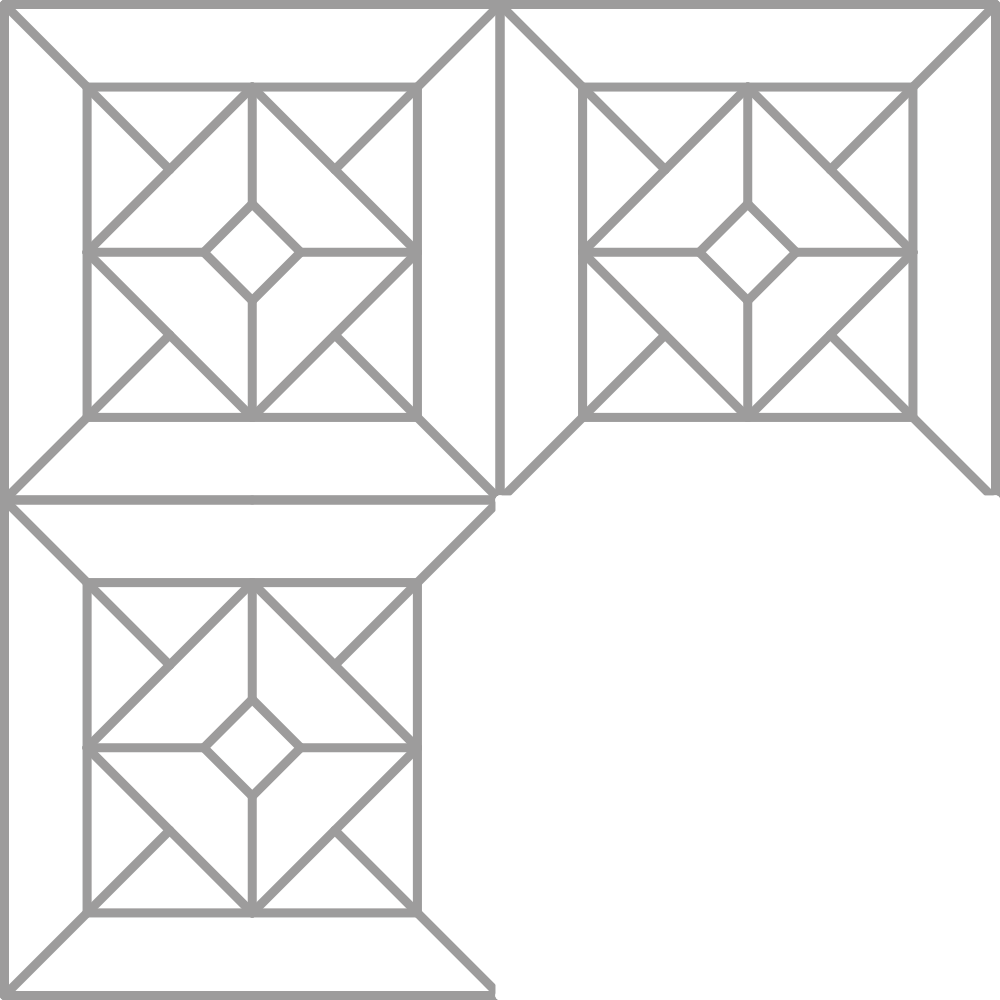

Striking and elegant, parquet encapsulates the essence of luxurious flooring. Formed of intricate arrangements of wooden shapes, this mosaiced floor style can be interpreted in a wide range of patterns, from chevron and herringbone to classic panels and beyond.

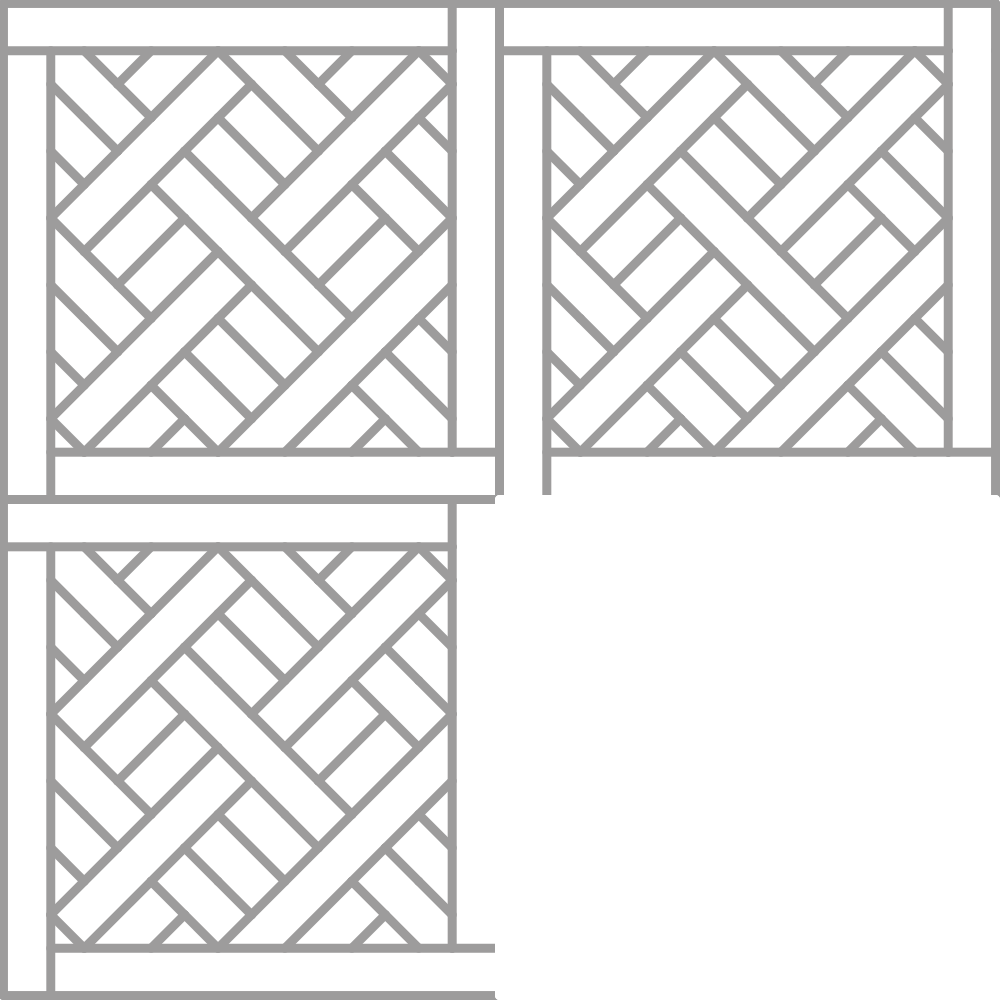

Hunter Oak Herringbone Pattern

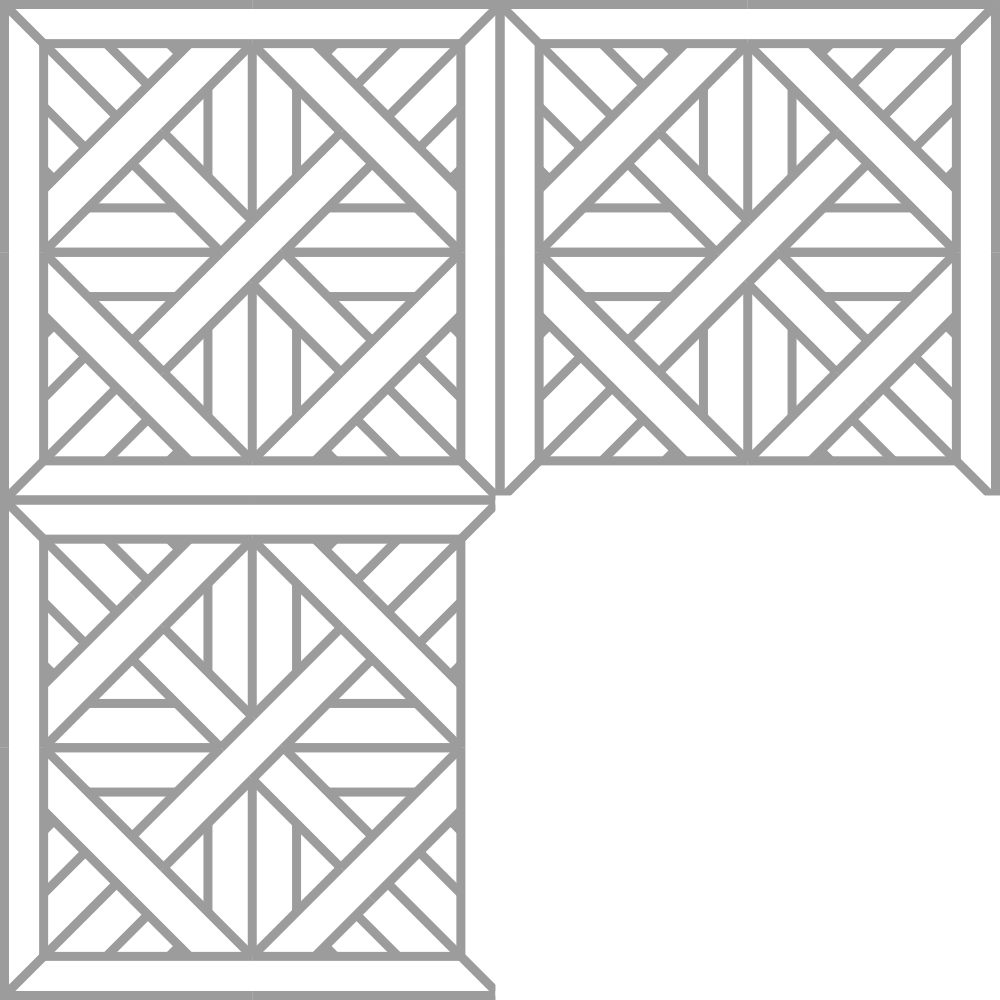

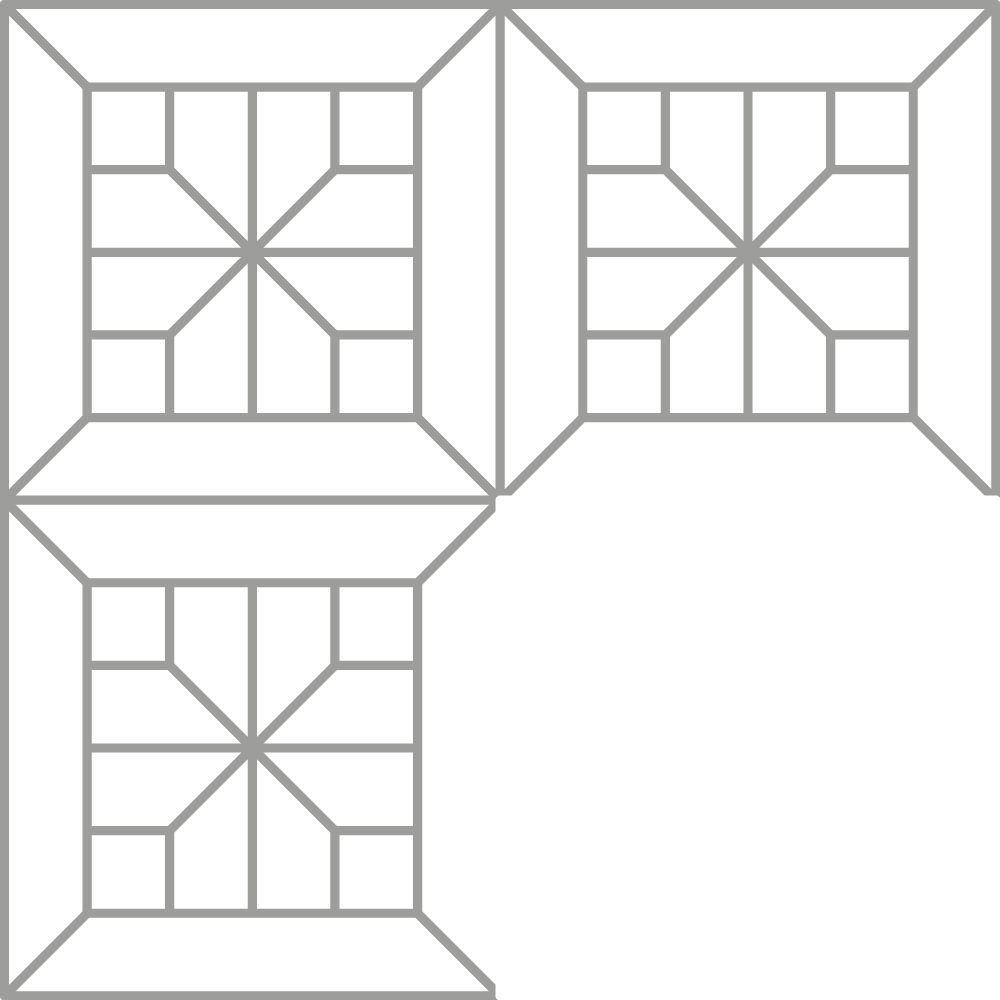

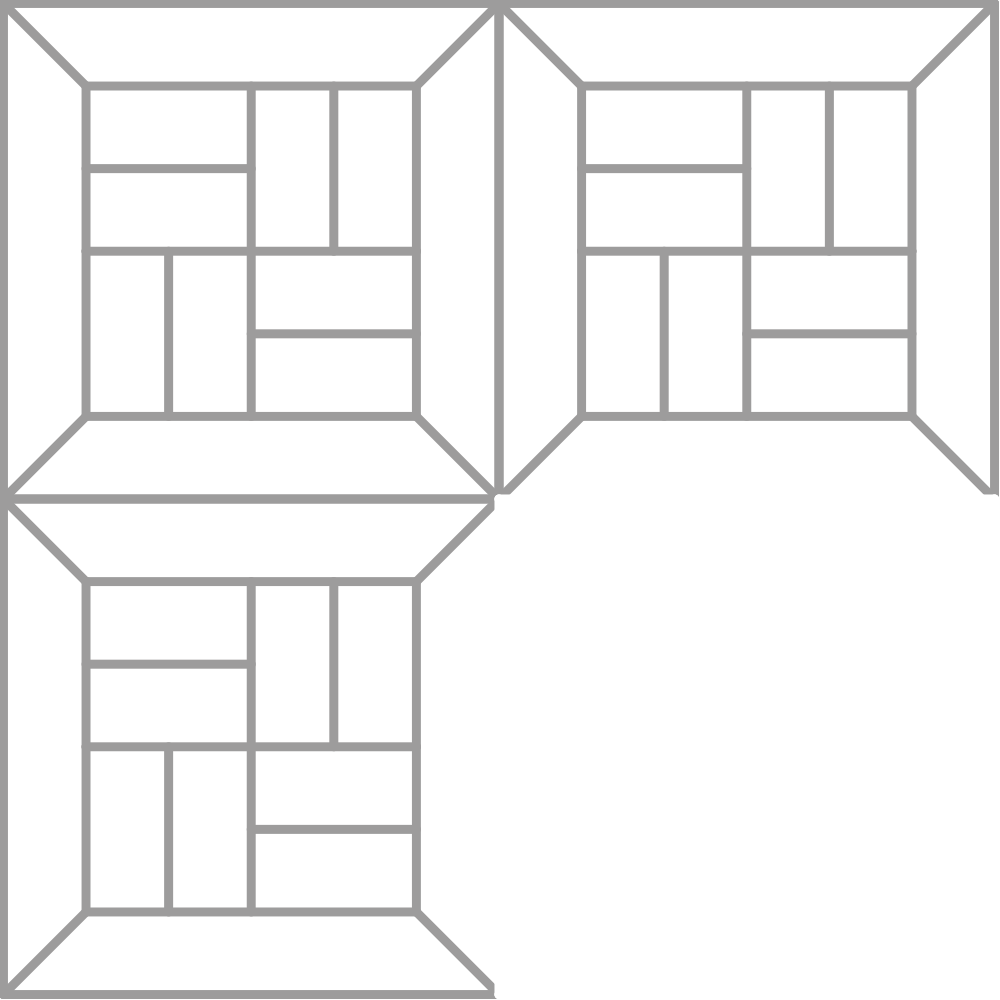

Antique Grey Bespoke Panel

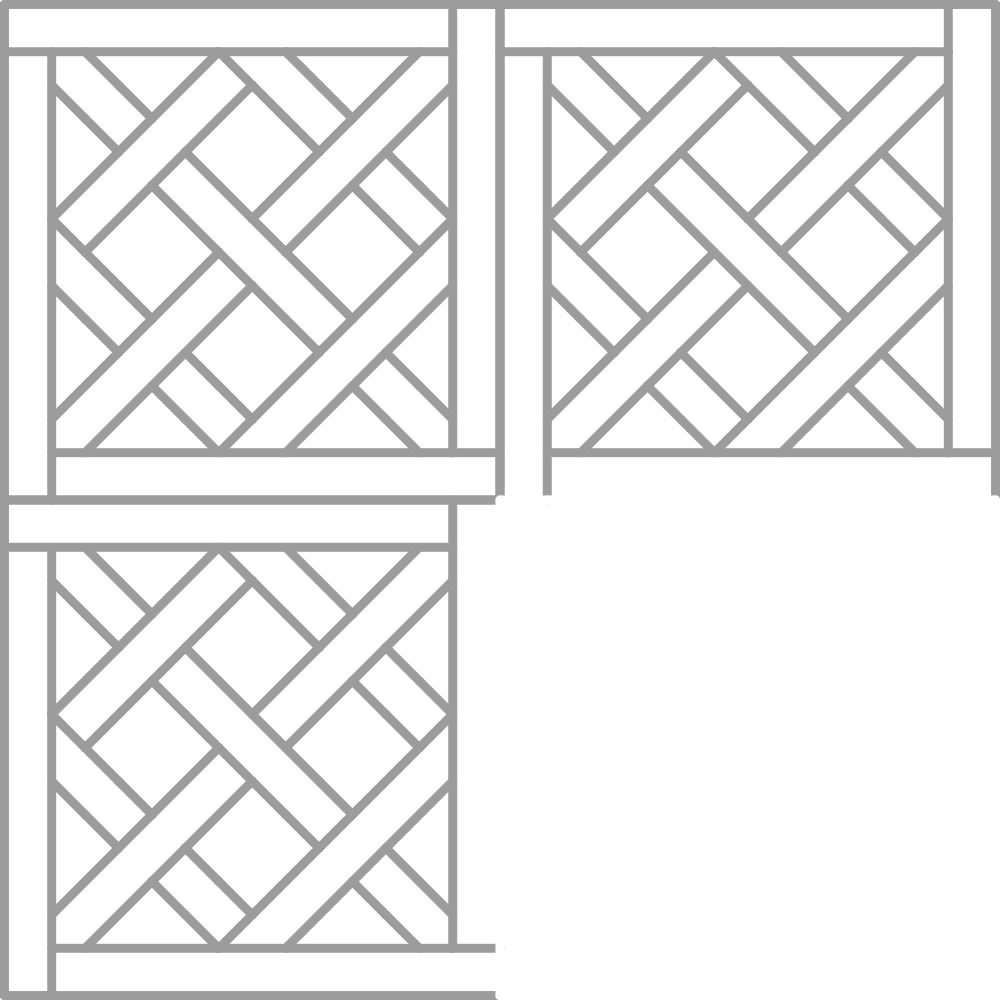

Ash Grey Chevron Pattern

Flooring Fit for a King

Whilst the history of parquet flooring can be traced back to 16th century France, it was King Louis XIV who propelled the style to international fame after installing elaborate parquet designs throughout the Palace of Versailles in the 1680s. Demand for Versailles panels and panelled parquet flooring soon soared, with parquet still hugely popular today.

Fired Oak

Why Choose an Element 7 Parquet Floor?

Crafted with the finest raw materials, our hardwood parquet flooring is engineered to an exceptionally high standard. Consequently, their durability and structural integrity are quite litterally second to none.

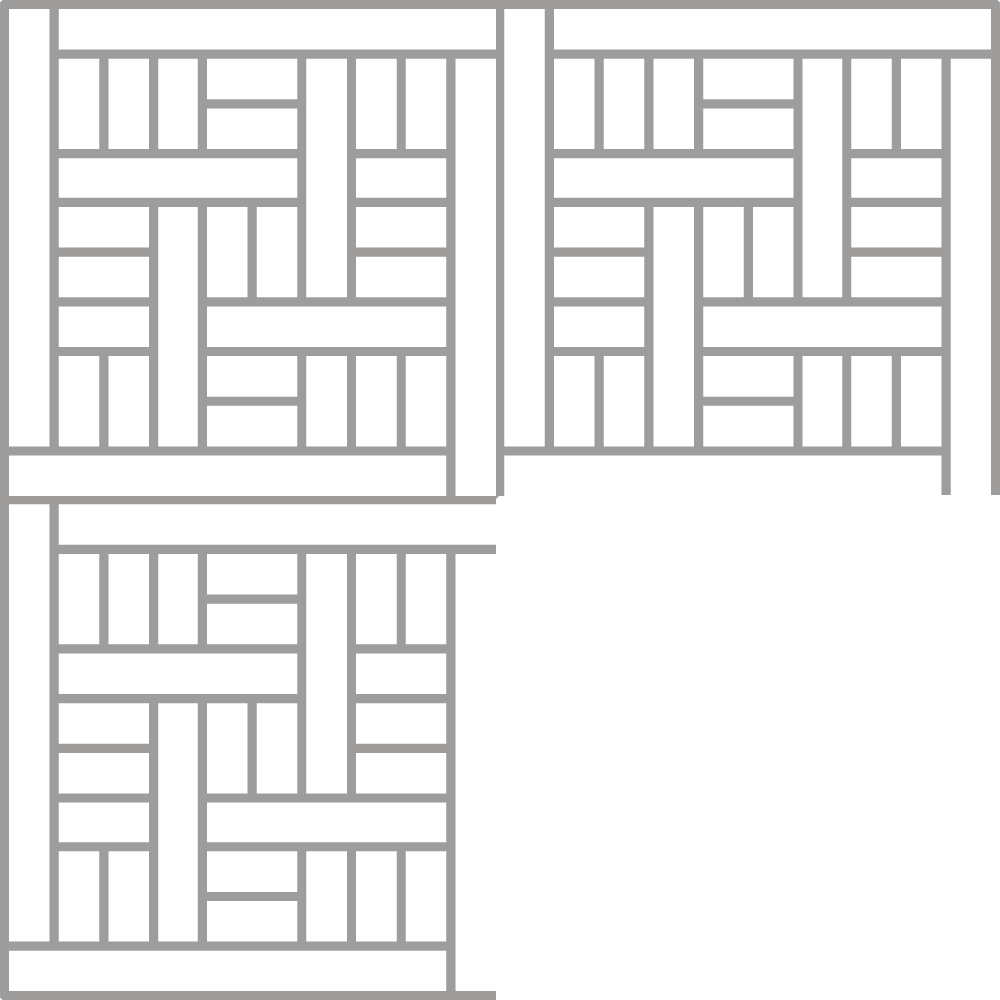

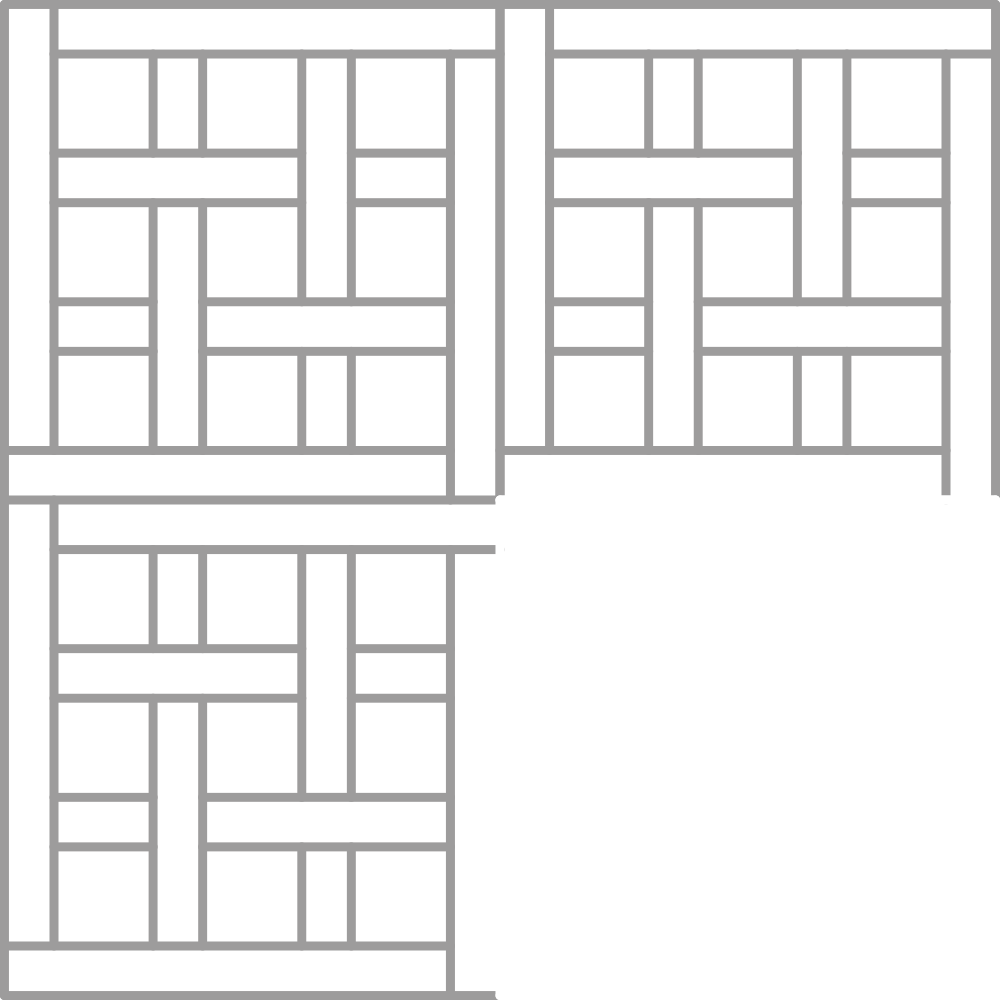

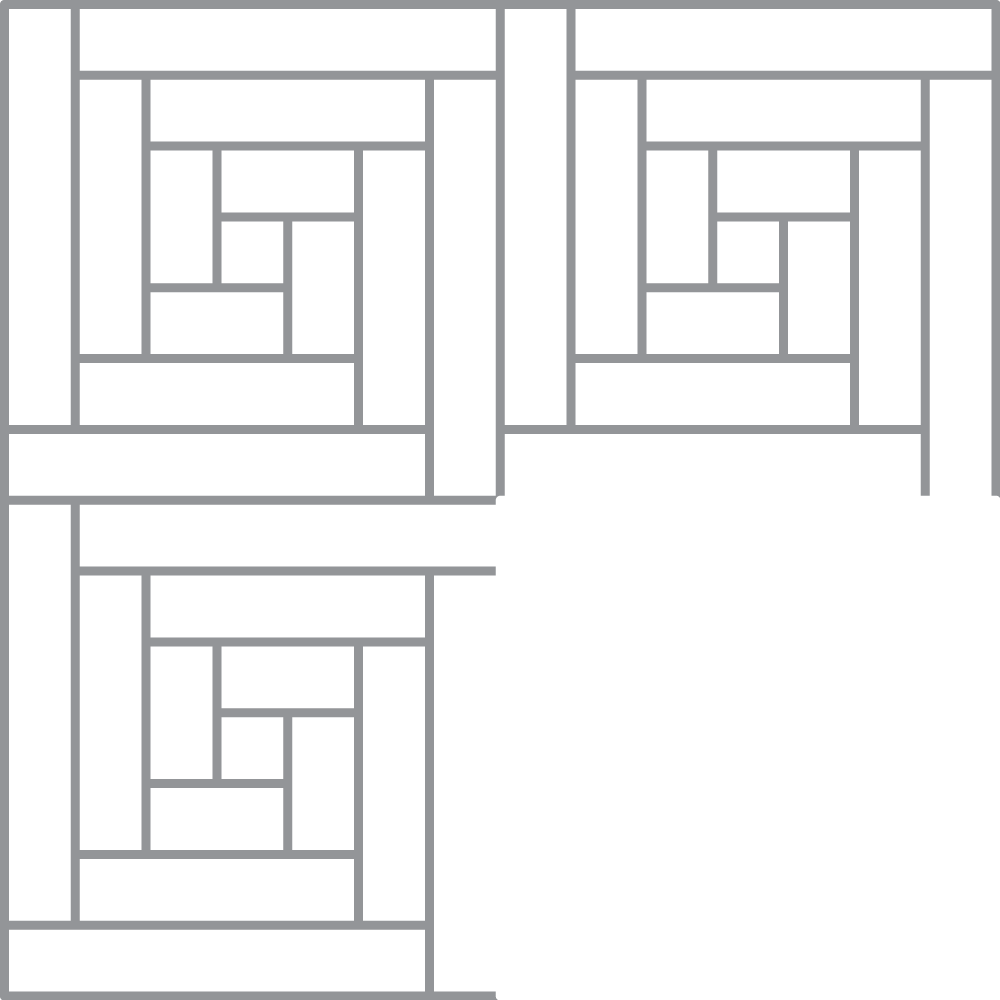

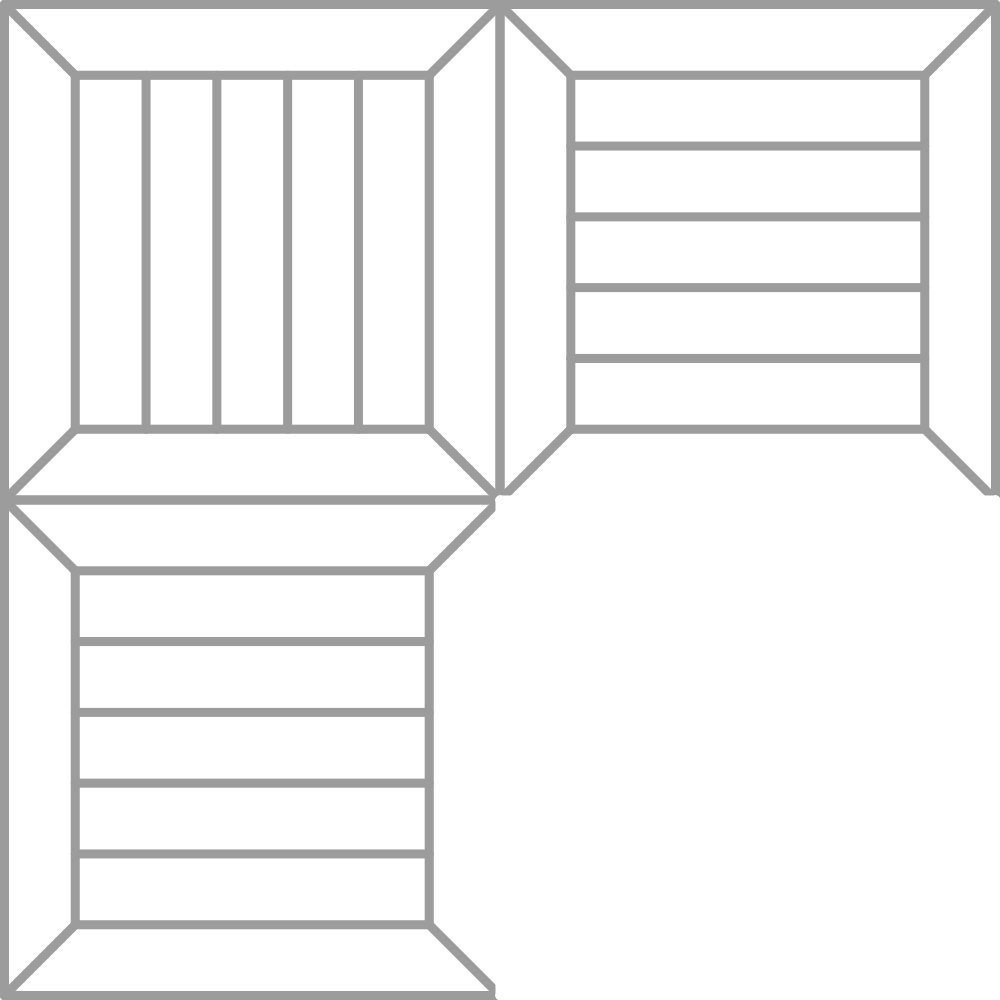

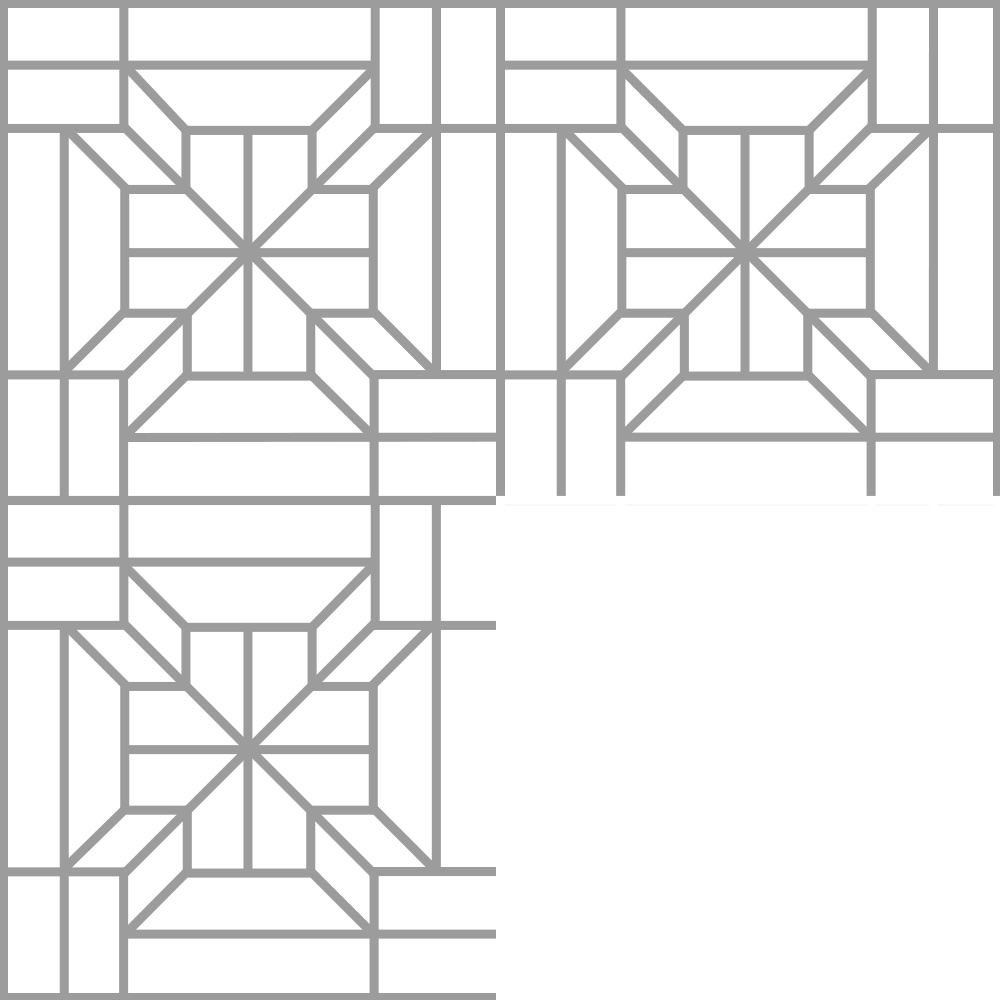

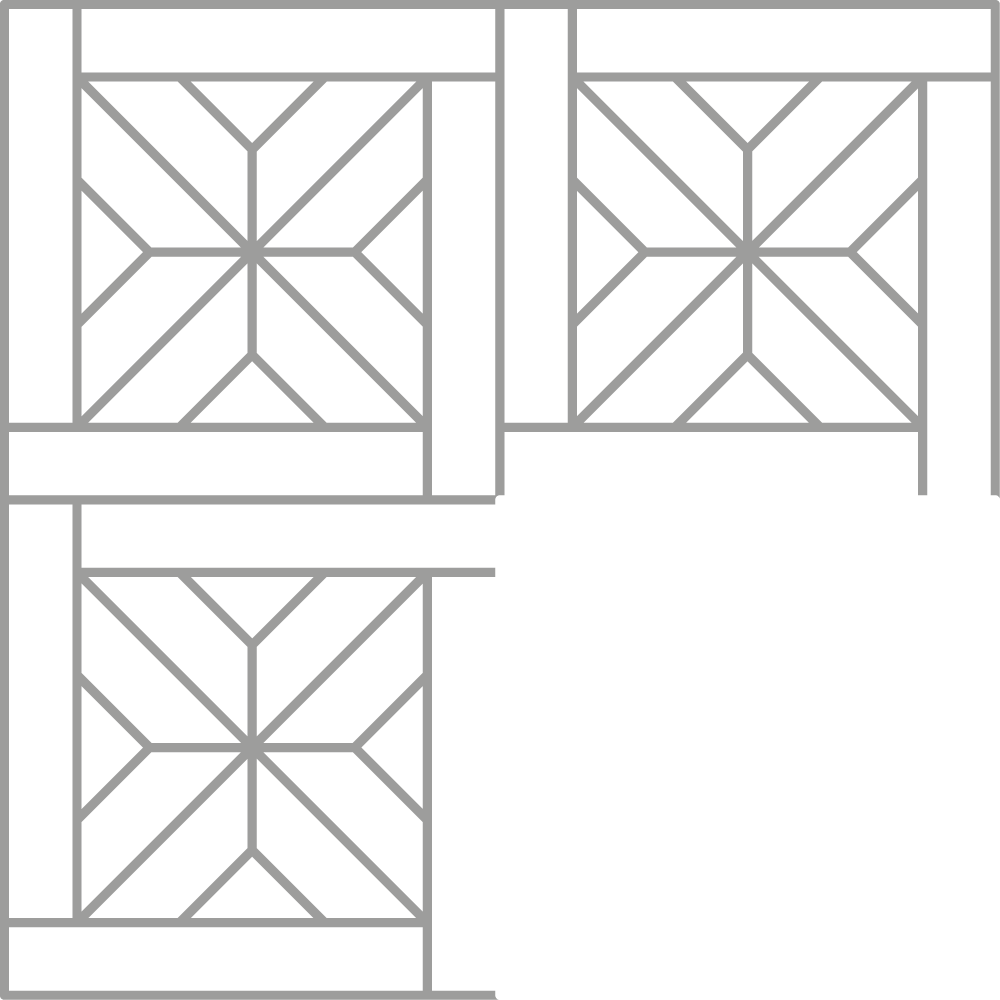

A Myriad of Patterns and Colours

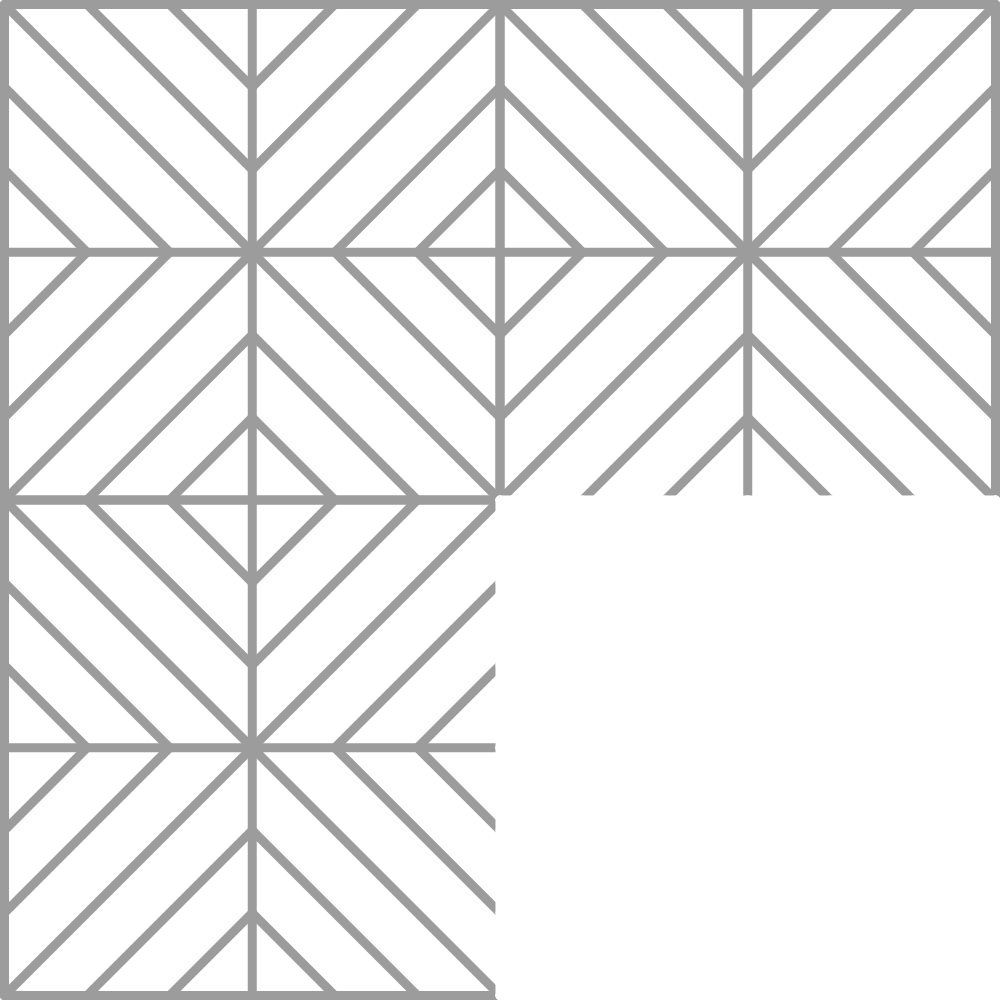

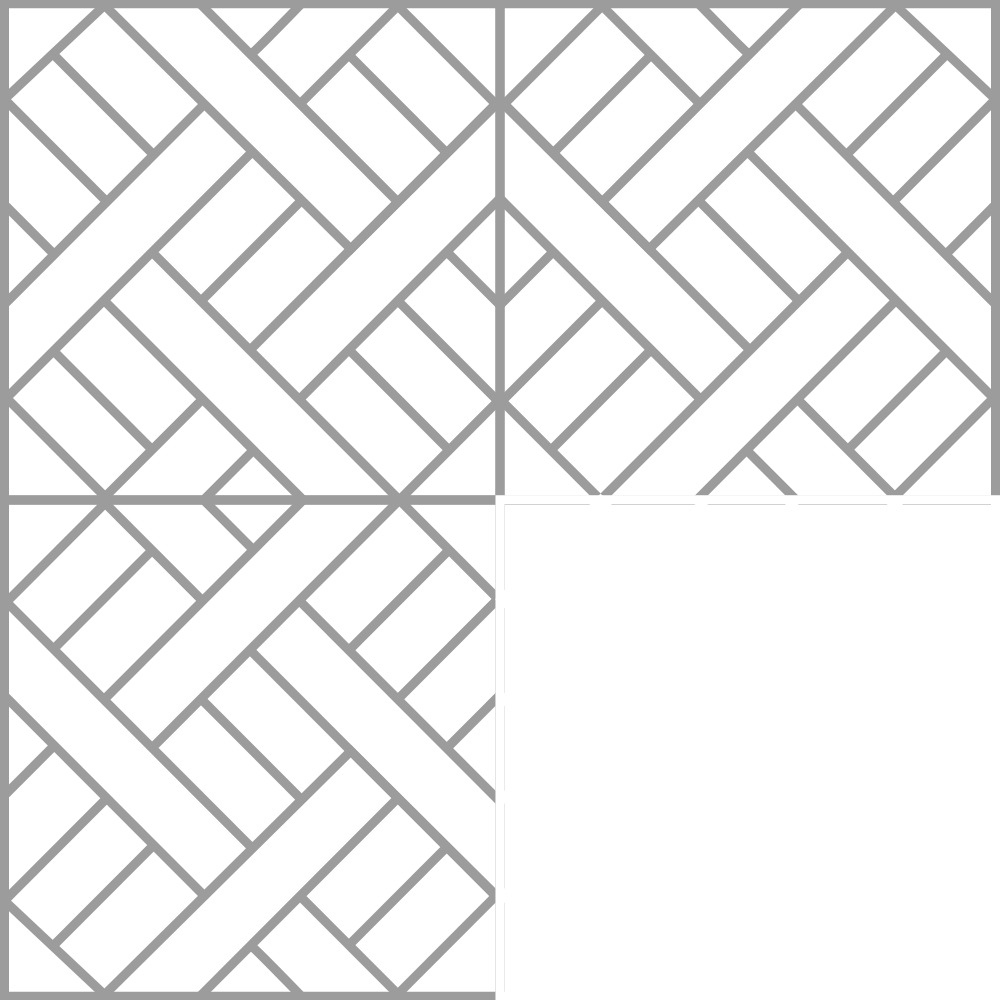

We offer parquet flooring in a wide variety of colours, wood types, pattern designs and pre-constructed parquet panels, allowing you to create your perfect parquet floor. Bespoke designs are also available upon request.

The Finest Materials

Our floors are crafted using raw materials of the highest quality. Sustainably sourced from European forests committed to responsible practices, our exceptional-grade timber is expertly milled in Italian factories to meet our own meticulous standards.

Made to Last

Standard wooden floors typically need refinishing – or even replacing – within a few years. However, Element7’s exceptionally stable parquet flooring combines traditional craftsmaship with cutting-edge engineered construction to deliver floors designed to last a lifetime.

Finish

The last stage of the engineering process, our technically advanced, eco-friendly lifetime finishes seal the deal. Our varnished finishes are applied in 8 coats for exceptional durability, with proper care and maintenance, your floor will never need to be refinished.

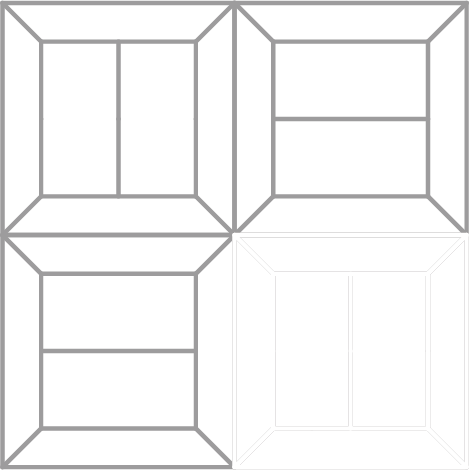

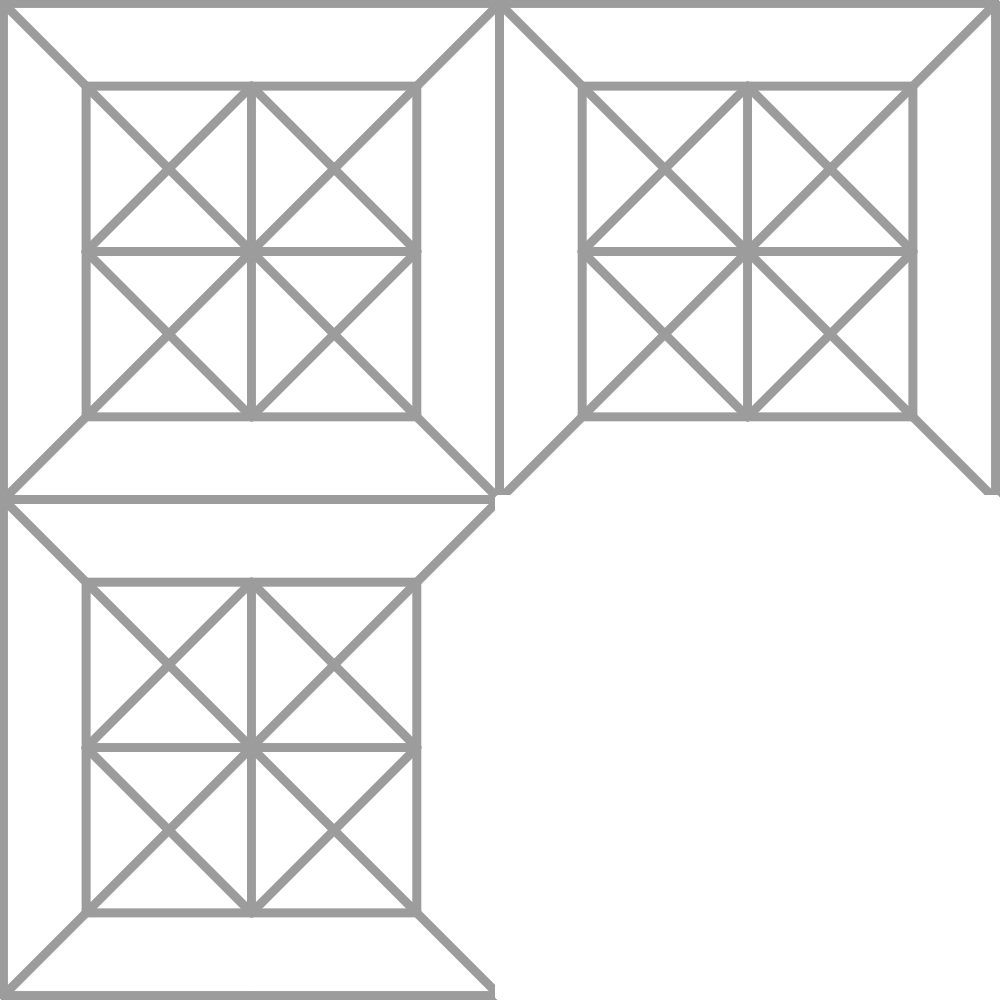

Parquet Patterns

I have worked with Element7 on many high-end residential projects over the last 20 years and have always found them to be the leading engineered hardwood flooring company. Exceptional site work and after-care. I can highly recommend them to clients and contractors alike.

Juliette Byrne

(Telegraph Top 20 / House and Garden Top 100)

Colours, Species and Finishes

Explore our extensive range of sustainably sourced wood species, delivered in a myriad of colours and our unique, durable, environmentally friendly finishes, designed to suit every project.

Sample Request

Select from our extensive range of wood species, designs and colours to suit your project.

Showroom appointments

Schedule an appointment with a member of our expert team at our London Showroom.